In single-port minimally invasive surgery, both the endoscope and three surgical instruments need to access the patient’s cavity via a single incision. To complete the surgery, the endoscope is required to provide illumination and be able to adjust the field-of-view freely, whereas the surgical instruments need to have a wide range of motion, precision movements and sufficient payload capacity. This results in the compact layout of surgical instruments and the complex design of driving and transmission mechanisms in a single-port laparoscopic robotic system. Meanwhile, ensuring the functionality and reliability of surgery poses extremely high demands on the robotic system development. Currently, single-port laparoscopic robotic systems often use a combination of positioning robotic arms and multi-degree-of-freedom surgical instruments. The robotic arms place the trocar to the desired positions and are kept stationary during surgery, while the surgical instruments are deployed inside the patient’s cavity for operation.

In this paradigm, the endoscope and surgical instruments access the patient’s cavity through a multi-channel single-port trocar. The actuation and control of surgical instruments that achieve wide-ranging, high-load, and highly reliable motions become the most critical technology.

Revolutionary “Actuation and Control Technology for Deformable Continuum Mechanism”

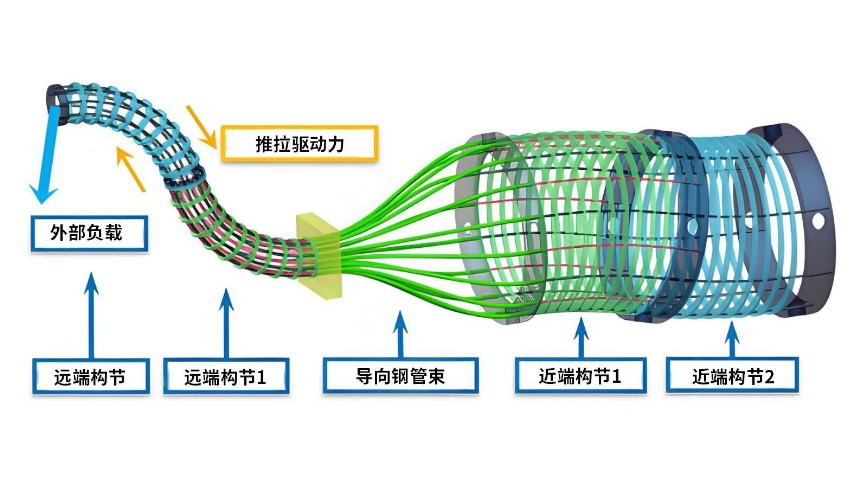

The revolutionary “actuation and control technology for deformable continuum mechanism” is the core technology adopted by the SHURUI robot’s surgical instruments and 3D endoscope. As shown in the diagram, the continuum mechanism consists of two proximal segments, a group of guiding cannulae, and two distal segments, with over a dozen of superelastic nickel-titanium alloy rods serving as structural backbones routing throughout the segments. The bending of the proximal segment results in the pushing and pulling motions of the structural backbones, which are transmitted to bend the distal segment, causing the distal segments to bend in the opposite direction. Adopting the “actuation and control technology for deformable continuum mechanism”, the surgical instrument is integrated with a two continuum segments, in which the driving motors for the proximal segments are placed outside the patient’s body, while the distal segments as a part of the surgical instruments inside the patient’s body can achieve dexterous movements with the omni-directional bending of each segment under the coordinated pushing and pulling of the backbones.

The “actuation and control technology for deformable continuum mechanism” offers numerous advantages: Over a dozen structural backbones can simultaneously withstand pushing and pulling forces, significantly increasing the load capacity of the snake-like surgical instrument; the redundant arrangement of structural backbones ensures that even if one fractures, the overall performance of the surgical instrument is barely affected, resulting in exceptionally high safety; the snake-like instrument exhibits continuous bending and deformation characteristics, enabling it to easily navigate through complex-shaped lumens or cavities, meeting various motion requirements in single-port surgery.

Important Notes

Important Notes

The SHURUI Single-port Endoscopic Surgical System (SR-ENS-600), developed and produced by Beijing Surgerii Robotics Company Limited, has obtained the CE marking for urologic laparoscopic surgical procedures, gynecologic laparoscopic surgical procedures, general laparoscopic surgical procedures, and thoracoscopic surgical procedures. It is intended for use by trained surgeons in an operating room environment in accordance with the representative, specific procedures set forth in the User Manual.

Safety and Performance Information

Beijing Surgerii Robotics Co., Ltd. owns Surgerii®, SHURUI®, and other trademarks and may not be used without permission.